Yeti‘s main products were cooler boxes before 2014. When they start the business of s/s drinkwares, Yeti brought huge changing on the global market of vacuum drinkware industry, and also lead new design trending in this industry until now. Now, Yeti has been one of the top players in this industry. It’s Yeti making 20oz and 30oz rambler tumbler a best seller on global market. So, many companies are curious what’s yeti tumbler manufacturing processing, and how to make custom tumbler similar as Yeti’s… Let’s go to probe the secret.

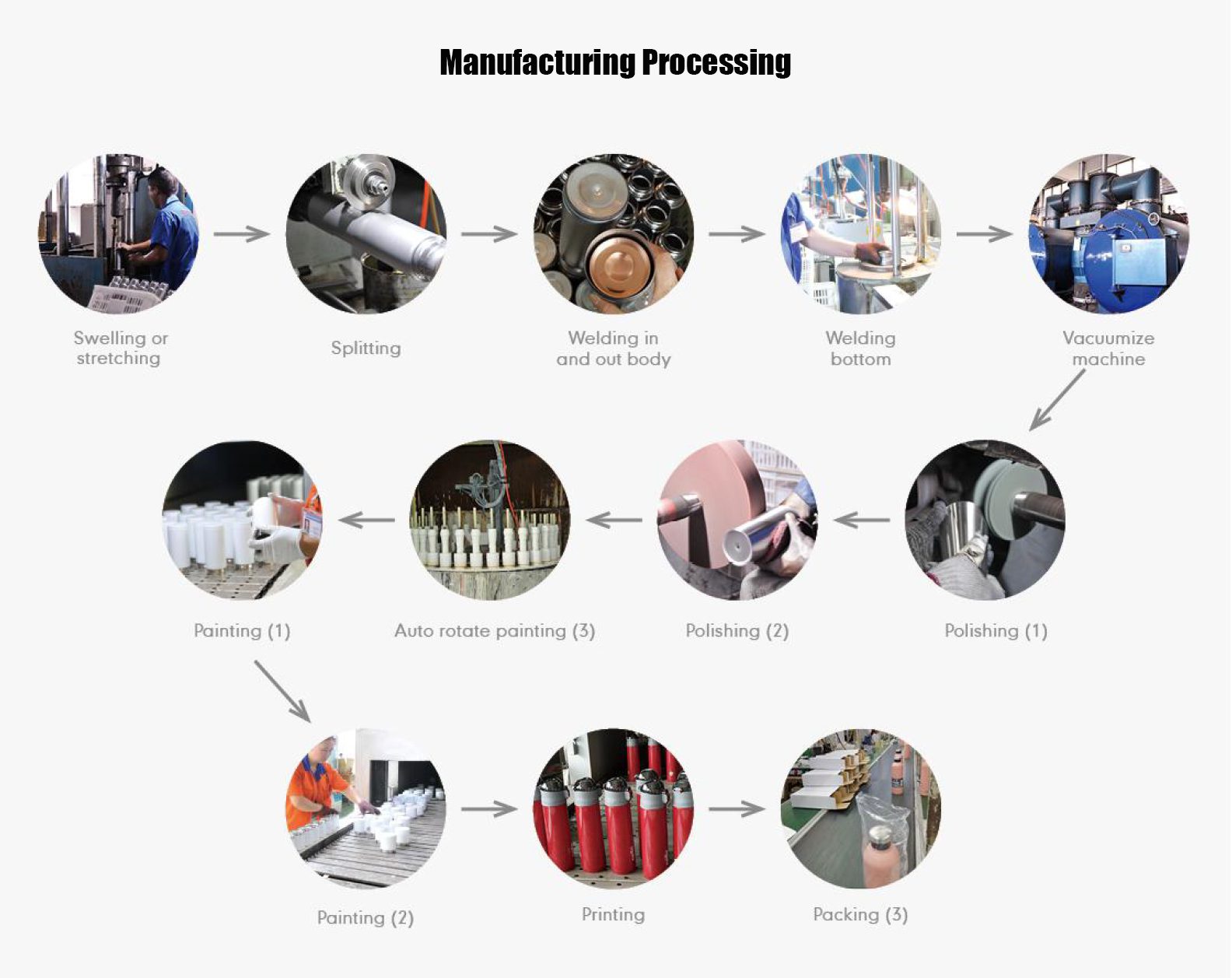

Yeti tumbler manufacturing processing.

As we all know, Yeti rambler cup is a type of thermal insulated drinkware product. Nearly all s/s insulated drinkware have similar product structure: double wall stainless steel, with vacuum insulation space between outer s/s shell and inner s/s shell, to isolate the temperature outside, to prevent the heat radiation of drinks inside the container.

So the same as other thermo insulated drinkware, there’re 7 major manufacturing processing for yeti tumbler mugs: 1. hard metal production of outer shell ; 2. hard metal production of inner shell; 3. combine inner and outer shell; 4. vacuumize processing for yeti cup body; 5. polishing inside and outside; 6. Coating decoration and logo printing; 7. Assembly, packing and inspection.

Now that we are introducing the whole production processing for yeti tumblers, let’s go deep and detail…

I. Outer shell production:

- Pipe making: Fristly, make raw stainless steel roll into stainless steel pipe.

- Pipe cutting: Then cut s/s pipe into short pipe with double length of 2 tumblers.

- Hydraulic shaping: swelling the cutting pipe into the basic shape by hydraulic shaping machine.

- Raw tumbler splitting: as mentioned in 2, there’re 2 tumblers on one swelling pipe. This process is to cut them into 2 outer shells.

- After splitting process, next step is to cut off the surplus part on the top of outer shell.

- Smoothing the top rim and bottom rim of outer shell, to provide good rim condition for further welding.

- Make circle rib on the bottom of outer shell… this circle rib is built for outer base combination.

II. Inner shell production:

- Make raw stainless steel roll into stainless steel plate, then cut the steel plate into small round pieces.

- Deep drawing process for inner shell: the shaping method for inner shell and outer shell are different. The inner of yeti tumbler is seamless, which is not made by hydraulic swelling. We need to shape the inner shell by deep drawing.

- After deep drawing, next step is to cut off surplus part on the top of inner shell.

- Smoothing the rim of inner shell mouth, to provide good rim condition for welding.

- Copper plating: make copper plating layer on the outer of inner shell. This can make the tumblers with better heat retention performance.

III. Combine inner and outer shell.

- Combine inner shell and outer shell together, then weld the top edge of joint rim.

- Making middle base: there is a vacuum hole on the middle base, then weld an air-getter onto the middle bottom, which will be helpful to speed up the vacuum processing for yeti insulated cup.

- Adding middle steel base on the bottom of above combined piece, then welding and seal the middle base.

IV. Vacuumize processing.

- Vacuum processing: there’re two kind of vacuum processing method: pipe vacuum processing & no pipe vacuum processing. For yeti tumbler production, most of factories use no pipe vacuum processing.

- All the semi-tumbler, generally 80-120pcs as batch, will put on a steel tray, by top down and bottom up.

- Put a small piece of solder on the place of vacuum hole on middle. This solder will melt when temperate reach 900 degree.

- Put whole tray of semi-tumblers into the vacuumize oven. Setting right heating temperature and time. Start to heat the tumblers inside. By 600degree heating 30-45 mins, the air inside the space gap between inner and outer shell, will be exhausted from the gap with time going… this process will make tumbler reach 99.999% vacuum rate in gap between inner and outer.

- Then oven will increase temperature to 900degree…the solder on bottom will melt to seal the vacuum hole.. The oven stop heating and cool down. The whole vacuum processing is completed.

- The final step of the processing is to make vacuum rate checking.

V. Polishing inside and outside:

- After finishing vacuum processing, we will send these tumblers for electrolysis polishing. It’s a way to polish tumbler inner. It can remove all contaminates and greasy dirt inside the tumbler. After electro-polishing, inner shell will become shinning.

- Polishing the outer shell by machine, to remove the oxide layer and dirt on the outer shell of yeti mugs.

VI. Coating decoration and logo making:

- Powder coating spray on outer. Some steel finish tumblers don’t need this process, but most of insulated tumblers will be coated with powder coating in various colors.

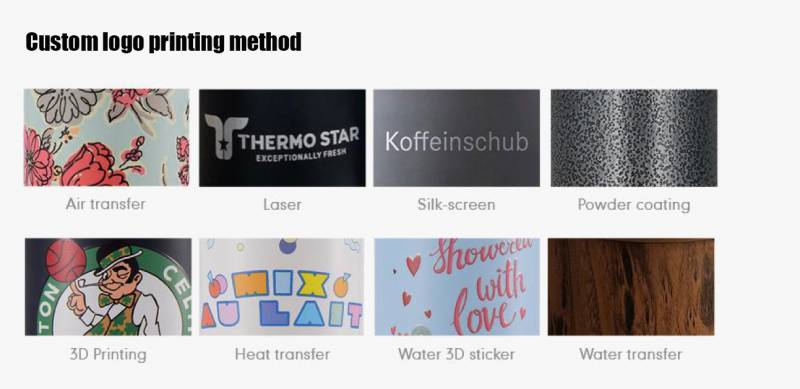

- Logo printing or engraved logo for yeti tumbler. Actually, for yeti tumbler, the logo is embossed on the outer shell. For alternative tumbler, we suggest laser engraving and screen-printing logo, which have lower MOQ and lower cost.

- For some yeti rambler tumblers, there is full colors pattern printing on whole cup. Generally, it will use gas-transfer printing or water-transfer printing to make full wrapped pattern on the tumbler cup.

VII. Assembly, packing and inspection:

- Adding the outer s/s base onto tumbler body by pressing

- Add lid onto the tumbler. There’re several lid options: Yeti standard lid, magslider lid, slide lid and flip lid.

- Add paper wrap on the Yeti tumbler mug, packed into unit box, then into shipping carton.

- Pre-shipping inspection: internal inspection by manufacturer, and external inspection by client, to make sure the quality of yeti mugs meet general quality standard.

Where is Yeti tumbler manufactured?

After introducing the manufacturing processing of yeti tumbler, we need to make brief instruction on where is yeti tumbler made and who produced them. Are yetis made in USA? Of course not. All yeti tumbler cups are made in Zhejiang, China. The 3 major manufacturers for yeti drinkware, all located in Yongkang, China — a small city located Zhejiang province, known as the city of hardwares, the city of vacuum flask in the world. Actually around 60% insulated bottle and tumbler products in world are produced in Yongkang area.

YONGKANG PICTURE OR MAPS

Hono Housewares is also a manufacturer of insulated drinkware located in Zhejiang, China too. We can provide you various of insulated tumbler cup and bottle products, including 20 oz, 30 oz yeti rambler tumbler, wine tumbler, slim can koozie, insulated cooler, lowball cups and thermo growler products.

How to make custom yeti tumbler from China?

If you want to make custom yeti tumbler from China, or you want to know what does it cost to make engraving yeti cup, please kindly contact us. We will provide you more information about custom yeti tumbler, and we also provide you high quality alternative solution as yeti tumbler.

As mentioned above, we can provide you many styles of Yeti drinkware alternative products, and we can provide you several customized options for you to make your own design yeti tumbler. Here we would like to introduce what custom options we can provide to you.

Customized options and MOQ:

- Private mold: if you want to make your shape s/s tumbler body or your own lid design, we provide private mold services. We can open mold according to your idea and your drawing. Due to the high cost of mold, private mold tumbler requires high MOQ = 10000pcs.

- Custom color: if you want to make yeti tumbler custom color on lid or tumbler body, please just advise the pantone number, we can make the colors on the tumbler accordingly. The MOQ is 1000pcs to make custom color yeti cups. If you just want a small MOQ to start. We have many regular colors for your options:

- Custom logo: we can make your custom logo on the yeti tumbler by several logo making technique: screen printing, laser engraving, embossing and 3D digital printing. You just need send us the logo file, then we can give you suggestion on printing method. The MOQ of custom logo = 100pcs. If you want to make yeti tumbler with engraving logo, don’t hesitate to contact us.

- Lid options: we have several lids options for Yeti rambler tumbler 20oz and 30oz: standard lid, magslider lid, leak-proof slide lid and flip lid with straw holes, switch lid as below:

- Custom pattern printing: we can print pattern, picture or photos on the tumbler by gas-transfer printing, water decal printing or sublimation printing. The printing method and MOQ depend on what pattern you want to print.

- Custom package: we also provide private label, custom color box and other custom package for the custom yeti cups you order. Generally, the MOQ of custom package is 1000pcs to start.

If you want to know more detail information like tumbler options, prices and customized cost for yetis tumbler products. Please don’t hesitate to contact us. We believe you will find Hono a reliable supplier for custom yeti tumbler for you.